Description

NDT Inspection plugs and seals are used to identify and access Thickness Measurement Locations (TML’s) on insulated and non-insulated pipe and equipment to monitor structural integrity. These products are used in the Process Safety Management and Mechanical Integrity efforts underway in the refining, chemical, petrochemical, paper and pulp, household products, food processing, and transportation industries.

Features:

- Reduces time for periodic tests

- Patented design seals and protectsagainst corrosion under the insulation (CUI), chemical and UV exposure

- No transition gaskets needed for corrugated or elbow installations

- DuPont Product Approval

- Available in 4 sizes

Easy to Install:

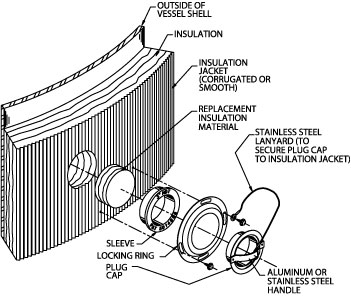

- Locate and mark the insulation jacket where the test is required.

- Use either tin snips or a hole saw to penetrate the insulation jacket with a circumference equal to the size of the NDT Inspection Plug to be installed. Remove the final layer of insulation in the safest and most convenient manner (using your hand or knife) to expose the substrate for electronic and visual inspection.

- After inspection, re-insert the insulation or replace with a high density material.

- Insert the Sleeve. (Caulk around the Sleeve for cold applications is recommended.)

- Install the Locking Ring and Lanyard (i.e. if applicable).

- Insert the Plug Cap to affect a seal.

Technical Specifications:

Material Specifications

The NDT Inspection Plug has two parts:

1. The Sleeve is made of 50 durometer EPDM as follows:- Ethylene Propylene Rubber

- Chemical Resistance: Excellent

- Ozone, Water/Steam Resistance: Excellent

- Permanent Set Resistance: Excellent

- Temperature Range: -65F (-54 C) to +300F (+149 C) for Continuous Operation

- Tensile Strength: 1400 PSI

- Elongation: 300%

- ASTM D2000 2BA 510 A14B13C12F17

The Sleeve is also produced in silicone for higher temperature applications.

2. The Plug Cap is made of dead soft aluminum #5052, or (304) Stainless Steel.Design Specifications

NDT Plug Size

Recommended for Insulation Jacket OD

1.5″ (38.1mm)

Small Diameter Piping

2.5″ (63.5mm)

Minimum 6″ (152.4 mm)

3.0″ (76.2mm)

Minimum 9″ (228.6 mm)

5.0″ (127.0mm)

Vessels & Equipment

Options and Accessories:

The Standard NDT Inspection Plug consists of an EPDM Sleeve and an Aluminum Cap.

The NDT2 Inspection Plug consists of an EPDM Sleeve and an Aluminum Cap, with a handle and stainless steel lanyard.

Sizes for either the Standard or NDT2 Inspection Plug are 1.5″, 2.5″, 3.0″ and 5.0″.

Other options include:- Lock Down Rings (Aluminum or Stainless Steel)

- Stainless Steel Caps (Standard or NDT2)

- Silicone Sleeves

- Color-coded Caps

- Identification Tags (With or Without Bar-coding)

- Inspection Plug Assemblies Mounted on Custom Plates

- Aluminium or Stainless Steel Sleeves for Asbestos Applications