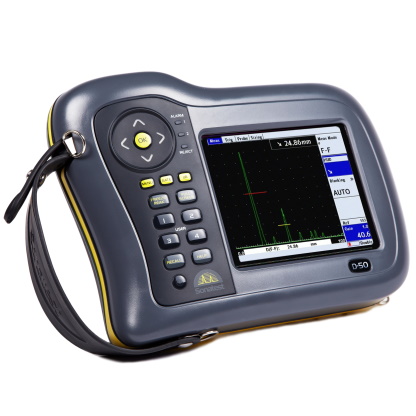

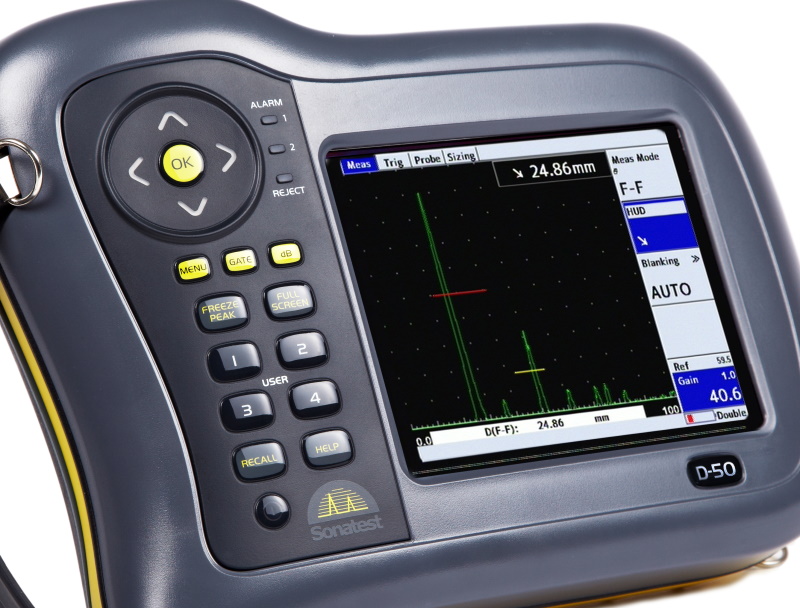

The Sitescan D-50 offers the end user an entry level broadband flaw detector in the popular and portable casing of the established D-Series; with a full VGA display, a 50nS (Spike) 200V, a Pulser 0.5dB gain resolution and an optional rubber boot.

Sonatest Sitescan D50

Description

The new Sonatest Sitescan D-50 offers the NDT end user an entry level broadband flaw detector in the popular and portable casing of the established D-series; with a full VGA display, a 50nS (Spike) 200V, a Pulser 0.5dB gain resolution and an optional rubber boot.

Features:

- Customisable & Inituitive Menus

- Split DAC/AVG/DGS

- Angle Measurement Mode

- Configurable on-board software

- Field Upgradeable

- Encoded B-Scan

- A-Scan Fade

- 4GByte on-board memory

- USB Interface for PC import/export

Sizing Techniques & Software Options include:

DAC (Standard)

Defined by up to 20 reference points or converted from TCG curve and digitally drawn on the screen. DAC curves meet the requirements of EN1714, ASME, JIS and many other standards. Custom DAC curves can be selected. DAC dynamic range can be extended by automatically adjusting the reference curve to match the reference gain. Scanning Gain and T-Loss available as separate controls. Amplitude readout is selectable between %FSH, % DAC or relative dB.

Split DAC & DGS/AVG (Option)

Adds up to 3 zones of added gain (+12db, +24dB) to the DAC or DGS/AVG curve to enable single-pass scanning of large sections and attenuative materials. Conforms to EN583-2:2001.

TCG (Option)

Time corrected or “Swept” gain, defined by up to 10 reference points or converted from a DAC curve. All points converted to 80% screen height.

Backwall Echo Attenuation (BEA) Option (requires TCG)

0-40dB attenuation applied to the latter part of the time base, to improve the detectability of defects near the back wall and the loss of BWE due to porosity.

AWS (Option)

Built-in calculation and display of factors and parameters required by AWS D1.1

AVG/DGS (Option)

Enables the calculation of pseudo “DAC” curve and equivalent reflector size of UT indications, based on user input of transducer parameters.

API (Option)

On-board flaw sizing method in accordance with API 5UE.

Interface Trigger (Option)

Unlocks the interface trigger gate controls, which hold off the A-Scan acquisition and display until an interface echo is detected within a specific range and amplitude. Used for the elimination of water-path.

Corrosion Software (Option)

Enables complex inspection plans to be uploaded from a PC using the on board UT-lity software. Features include 2 dimensional thickness logging, storing A-Logs and B-Logs with thickness values, taking multiple readings per location and note creation for each grid location. A B-Scan option available to display bar-graph views of thickness readings taken by Gate 1 against distance or time.