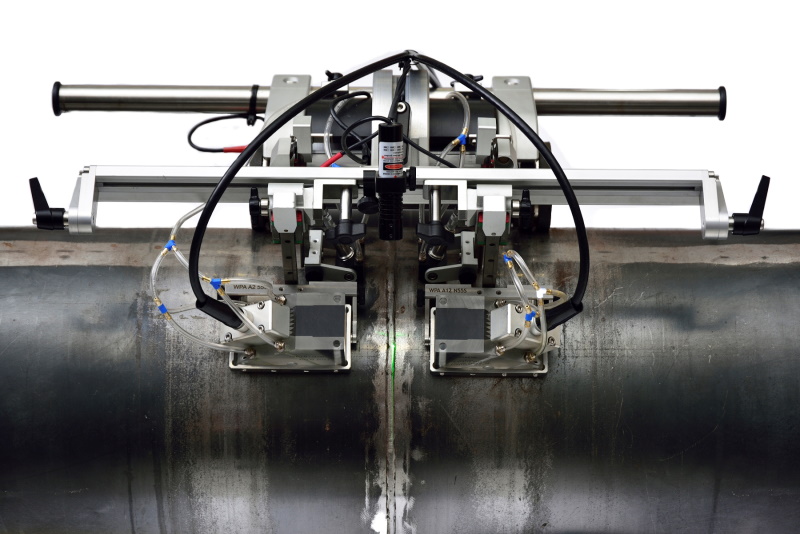

SAW Bug is a motorised, magnetic-wheeled buggy that can carry up to six ultrasonic transducers. It is designed for single axis automated inspections of circumferential welds on carbon steel pipelines from 4”OD up to flat. With a four-wheel drive system, the magnetic buggy has excellent grip and drive power and delivers constant speed whether ascending or descending the inspection surface.

Phoenix SAW Bug Scanner

Description

SAW Bug is a motorised, magnetic-wheeled buggy that can carry up to six ultrasonic transducers. It is designed for single axis automated inspections of circumferential welds on carbon steel pipelines from 4”OD up to flat.

With a four-wheel drive system, the magnetic buggy has excellent grip and drive power and delivers constant speed whether ascending or descending the inspection surface.

The standard SAW Bug holds four transducers: typically two phased array and two TOFD probes but can accommodate up to six probes. Its compact design makes it adaptable for the inspection of a wide range of welds from 4” OD pipes up to large vessels.

The single axis motor is controlled via a simple remote handset offering forward and reverse drive options and variable speed control for the non-steerable magnetic wheels. The motor power unit includes an emergency stop for safety and outputs the live motor encoder signals directly for connection to any industry standard instrumentation.

A corrosion mapping arm is also available, as an optional extra, for SAW Bug to carry out C-scan inspections.

- Low cost automated single axis inspection

- C-scan inspection with optional corrosion mapping arm

- Quick to setup and operate

- User-friendly operation with simple control handset

- Compatible with all instruments with encoding capabilities

- Powerful four wheel drive system gives excellent grip and performance to overcome small obstructions

- Laser guide for alignment

- No tools required, simple to adjust probe position with thumbscrew