Description

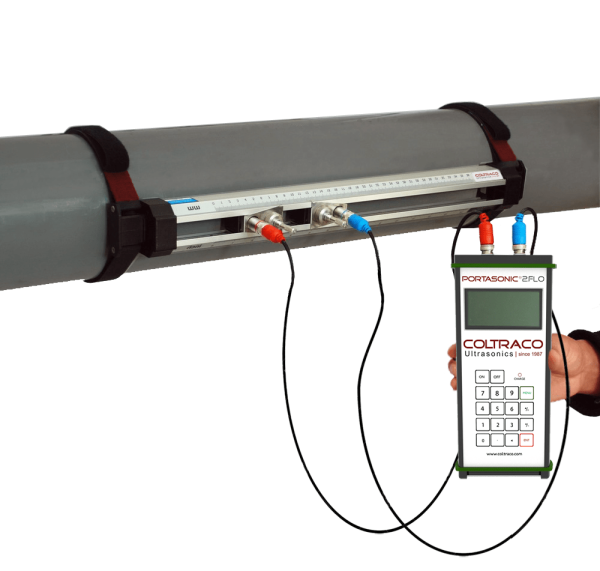

Portasonic 2.FLO portable clamp on flow meter: The Award Winning Portasonic to non-invasively measure the flow of any clean liquid through a wide variety of pipes. Can also be combined with the Portasonic® 2.FLO Calculator to calculate and store internal pressure readings!

Non-invasive utrasonic flow technology allows the internal flow of a pipe to be measured without the need to modify or acess the internals of the pipe in any form. Simply place sensors on the outside of the pipe, go through the setup process and instantly measure the speed and volume of liquid flowing through the pipe. This is used throughout proces industry, fire hydrant testing and numerous other testing and maintenance applications.

Key Features

- Versatile – Capable of working on pipes DN15 – DN 2500, across multiple different pipes/pipe sections. Large internal database of pipe, fluid and lining materials (19+ for fluids, 23+ for pipe and lining materials)

- Clamp-on – Clamp-on therefore no installation costs such as drilling into pipes and no downtime to the pipe network is present

- Reliable – Measures flow velocities between 0.01 m/s – 25m/s.

- Diagnostics – It has a built-in signal oscilloscope for sensor positioning and diagnostics to achieve maximum accuracy with the measurement while providing visibility of the potential issues with the installation for troubleshooting purposes.

- Non-Contact – The fluid cannot damage the flowmeter, which could contribute to a longer lifespan and lower maintenance cost compared to inline flowmeters which are in contact with the fluid and risk being damaged by the pressurised flowing fluid

BENEFITS

There are so many advantages and benefits of using the Portasonic® 2.FL0:

- Accurate to +/- 0.5% under ideal conditions. Resolution of 0.25mm/s. Repeatability of 0.15% of measured value.

- No risk: As there is no contact with the fluid being measured, there is no risk of pressure loss throughout your pipe network

- Long life: IP65 main unit enclosure. Battery life up to 12 hours’ continuous use, standard 9V PP3 battery

- Robust: Sensors temperature range -20°C to +150°C.. Sensors rated IP66

Technical specifications

Dimensions

220 mm x 85 mm x 33 mm

434grams

Pipe diameter range

DN15 mm to DN 2,500 mm

0.5inch to 98 inches

Please enquire to larger pipes

Liquid Types

Most clean liquids with a solid content less than 10%

Accuracy

+/- 0.5% of measured value under normal conditions

Flow velocity

0.01 m/s to 25 m/s

Resolution

0.25 mm/s

Repeatability

0.15% of measured value

Measurement Rate

1 Hz as standard

Measurement units

Flow velocity

Volumetric flow rate

Mass flow rate

Energy flow rate (heat quantity)

Volume

Mass

Energy

Display

Full 128 x 58 pixel graphic display with backlight

Power Supply

9V PP3 battery

12 hours continuous use

Operating temperature

Main unit : -10C to +65C

Sensor : -20C to +150C

IP Rating

Main unit – IP 65 enclosure

Sensors – IP 66

Sensor dimensions

Standard sensors – 40mm x 20mm x 25mm

Large sensors – 60mm x 30mm x 35mm

Cable length

1.5m as standard

additional lengths available on request

Warranty

Main unit – 3 Year Warranty

Sensor – 1 Year Warranty

Technical Support – Lifetime of the unit