Coating thickness gauges are suitable for rough on-site use as well as for laboratory measurements. They are user-friendly and the illuminated display makes it easy to read the measured values even in dark environments.

Pocket Surfix Coating Thickness Gauge

Description

The Surfix easy X are offered as Surfix easy X I with an integrated probe, and as Surfix® easy X E with external, firmly connected probe. Both variants are available as combination devices FN for coating thickness measurements on iron/steel and non-ferrous metals and as F-types for coating thickness measurements exclusively on iron/steel. Two proven measuring methods for the thickness measurement are applied: the magnetic and the eddy current process (DIN EN ISO 2178 and 2360). Both offer the highest precision even in the case of thin coatings, on steel as well as on non-ferrous metals. The FN types use both methods; The selection is done automatically when the probe is set on the measurement object.

Area of application

All probes of the Surfix® easy X family are designed with a V-groove thus enabling stable vertical positioning on level, cylindrical or curved surfaces. The gauges are use in many different industries and for various applications:

- In Paint shops

- For paint coatings and powder coating technology

- For automotive assessment and in car Workshops

- In steel construction, car manufacturing and ship Building

- At reception areas for incoming goods

- During the production process

- At final inspection and quality assurance

- In Laboratories

Advantages at a glance

- Calibration-free measuring: just switch on and measure

- Backlit Display for easy reading even in dark surroundings

- “Zeroing” (One-point calibration) enable precise and accurate measurment on flat, rough and curved surfaces

- Measurement on iron/steel and non-ferrous metals with automatic recognition of the base material

- Online-statistic (number, average, standard deviation, min, max)

- Large landing area for safe positioning

- Acoustic signal when a reading is recorded

- Switchabel unit µm/mils

- Manufacturer testing certificate

- 2 years warranty

Technical specifications Surfix® easy X gauges

| Design | optional integrated probe or external probe |

| Measuring range iron /steel | 0 – 3,500 µm |

| Measuring range non-ferrous metals | 0 – 3,000 µm |

| Accuracy | ± 2 µm + 2% of value(higher value is applied) |

| Resolution | 0 – 1,000 µm: 1 µm / 1,000 – 2,500 µm: 2 µm / 2.500 – 3,500 µm: 5 µm |

| Carbide pole tip | • |

| Calibration | Factory-, zero calibration |

| Statistics | Average, standard deviation, minimum, maximum |

| Display | backlit, 4-digit alphanumeric, height 8 mm |

| Operating temperature | 0° C to + 50 °C |

| Surface temperature | –15 °C to + 60 °C |

| Dimension gauge | 110 mm x 50 mm x 25 mm |

| Dimension probes | I-models: integratedE-models: 24 mm x 45 mm |

| Weight | I-models: 90 g incl. batteriesE-models: 140 g incl. batteries |

| Protection class | IP 52 (protection against dust and dripping water) |

| Standards | DIN, ISO, ASTM, BS |

| Warranty | 2 years |

Limit values

| Smallest curvature radius for convex surfaces | 5 mm |

| Smallest curvature radius for concave surfaces | 50 mm |

| Smallest operation height | Surfix easy X I: 125mm

Surfix easy X E: 50mm |

| Smallest measurement area | 10 x 10 mm |

| Smallest base material thickness – F | 0.5 mm |

| Smallest base material thickness – N | 50 µm |

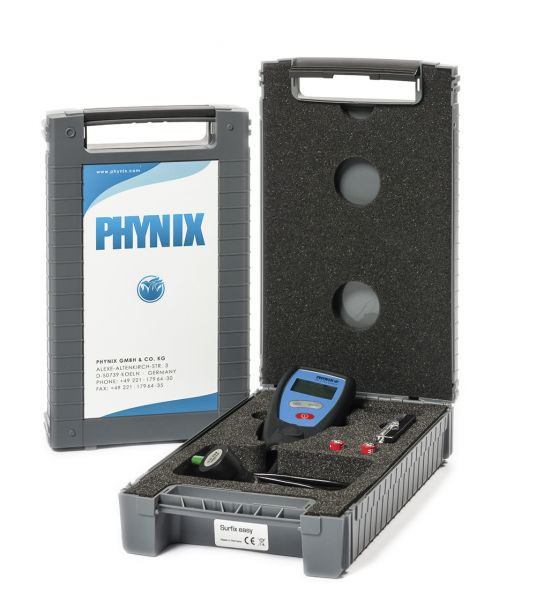

Included in kit

- Surfix easy X gauge incl. probe

- Rubber protection sleeve

- Standard foil(s)

- Zero standard(s) (steel/aluminium)

- 2 batteries AAA

- Operating manual

- Manufacturer‘s certificate

- Case