Description

Development of the Woodpecker

Coin tapping with a small hammer is used extensively at present to detect the debond of honeycomb structures in aircraft. Personal skills that take a long time to acquire are indispensable to keep accurate detection for coin tapping method, which depends on the difference in tapping sound between normal and debonded parts.

Because this traditional method depends on human senses, detection is difficult in a noisy environment and is impossible to continue with satisfactory accuracy over a long time. The inspector becomes used to unusual sounds or simply tired.

The fundamental problem is that the coin tapping method is not quantitative.

Mitsui has developed the Woodpecker to solve this problem. The Woodpecker uses automatic tapping, employing a central processing unit (CPU) to comparatively evaluate the output of a force sensor attached to the hammer, rather than depending on tone colors which are difficult to distinguish from each other in noisy environment.

The quantified evaluations are indicated with light emitting diodes (LED) and its digital values are transmitted to Woodpecker monitoring unit or personal computer.

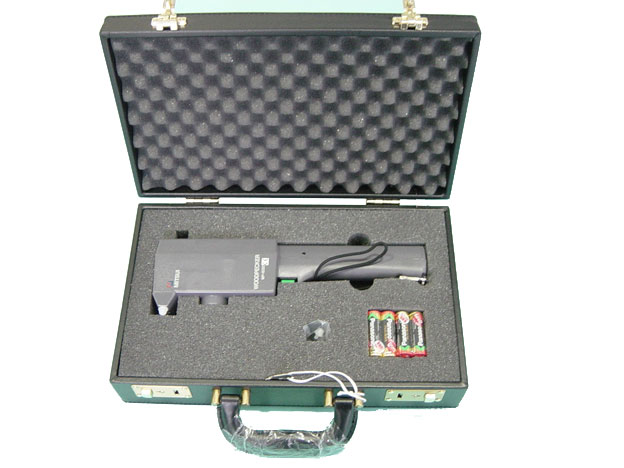

Development efforts emphasize the achievement of an extremely small size and lightweight to permit operation with one hand, a quantitative evaluation and a lower price than similar devices, resulting in a handy detector with excellent cost performance.

The WP632 can also be connected to WP632M, a separate monitoring unit available on option, for showing and memorizing of the measured values, when required, WP632M can transmit such data to a personal computer.

This unique and innovative WP632 can work even in a noisy place, and its quantitative display of defects is never interrupted in any environment.

Advantages of Tapping Method

The tapping method is superior to the ultrasonic nondestructive testing method in the following respects.

There are two types of debonds in the honeycomb or similar structure. The skin becomes debonded from the core and comes up loose, or it remains attached to the core even if debonded. The former debond can be detected with ultrasonic method, but the latter cannot, because the debonded skin and core would transmit the sound waves as if they are still boneded together.

Airbus Recommended & The NATO Stock Number approved (#6635-99-7089387)