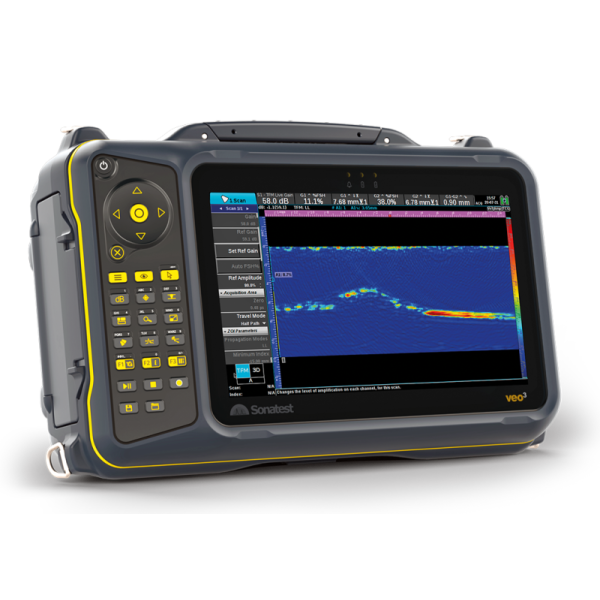

The Veo3 is the latest portable Ultrasonic Phased Array Flaw Detector from Sonatest. Features FMC/TFMi and new PCAP touch screen interface.

Sonatest Veo3 – Advanced Phased Array Flaw Detector

Description

Retaining the best features of the established Veo line, the new Veo3 now offers a PCAP touch interface, user templates, and more importantly, live TFM.

What does multi-technique mean? For some time, it has been widely recognised and accepted that welds can be inspected using both Phased Array and TOFD. Imagine an instrument that can not only perform live TFM but also concurrently present PA and TOFD in one single acquisition. As the three inspection techniques are complementary, the Probability of Detection is significantly increased. Furthermore, the time saved is considerable: one pass, one setup, one file, one position reference, one analysis.

Built on more than 60 years of dedication and knowledge, Veo3 integrates the latest technologies available to offer an impressive 6 hours of battery life in a modern, rugged, and lightweight enclosure. The Veo3 can generate TFM images of up to 500K pixels with a maximum resolution of 100 pixel per mm – and without limiting the number of pixels per axis. Phased Array, TFM and TOFD can be combined simultaneously for up to 8 scans.

Superior Digital Technology

The Veo3 offers superior data throughput and unsurpassed computational capacity. It delivers fast and accurate results using an impressive 32 channel PA beamformer that provides exceptional SNR, using enhanced digital signal processing.

Data file size is not a concern for the Veo3 thanks to its 64-bit Linux operating system because it can count on a fast 128GB SSD memory capacity allowing you to record huge amounts of information in a single acquisition file.

With its advanced technology the Veo3 is unique in allowing real-time multi-scan/multi-technique capabilities. Simultaneous TFM, PA and TOFD views are now possible.

Intuitive Menus and Workflow

The intuitive menu system is application and workflow driven, with set up and operation swiftly becoming second nature. Integrated help and wizards guide the user through scan set up whilst optimisation tips ensure the Veo3 always performs at the highest level. Fast and efficient wizards for sound velocity; wedge delay, TCG, DAC, TOFD setup and encoder calibration are all provided as standard.

The inspection plan shows the operator in 3D where probes are positioned on the test part, simplifying the inspection set up and providing an inspection reference for reporting. Using the latest computer technology, data can be permanently recorded for processing and report generation. All adjustments to focal laws are instantaneous, with angle resolution to 0.1° and up to 1024 focal laws without loss of performance.

FMC/TFM

With its unique architecture the Veo3 can generate up to six live TFM scans, produced from multiple FMC sources on different probes, and also generates TFM images of up to 500k pixels with a maximum resolution of 100 pixel per mm without limiting the number of pixel per axis.

All of the data received during Full Matrix Capture (FMC) scanning can be recorded on the Veo3. As a result, further detailed analysis can be performed including comparison with previous inspection data to identify trends and flaw/corrosion growth rates.

The Veo3 can combine up to 4 live TFM modes. As known as TFMi™, the details of the defects have never been so close to the reality. That imaging scan provides a high-precision height assessment and an improved shape accuracy compared to conventional PA inspections.

The ability to characterise the type of defects is now effortless. This technique has indeed demonstrated superior results on weld analysis.