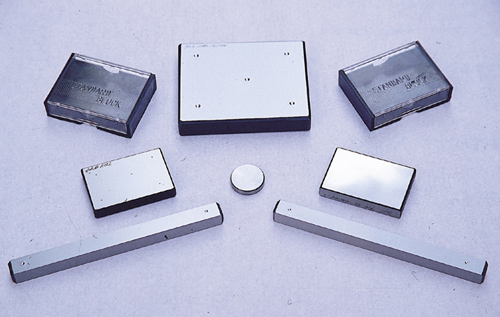

Description

They are separately used to calibrate various series of Hardness Testers.

Features and Use

- Conforms to National standard ” calibration of hardness reference blocks”

- Authorized by the General Administration of Quality Supervision, Inspection and Quarantine of the P.R.C.

- High homogenization and good repeatability

| Description | Range of Hardness | Dimensions (mm) | Weight (kg) |

| Brinell standardized block | 200±50HBS 100±25HBS |

100 x 80 x 16 | 1 |

| Rockwell standardized block | 80-88HRA 85-95HRB 20-30HRC 35-55HRC 60-70HRC |

60 x 40 x 10 | 0.19 |

| Vickers standardized block | 200±25HV5 450±50HV5 450±50HV10 450±50HV30 750±50HV10 |

60 x 40 x 10 | 0.19 |

| Superficial Rockwell standardized block | 89-91HR15N 42-50HR30N 75-80HR30N 37-61HR45N 87-93HR15T 70-82HR30T |

60 x 40 x 10 | 0.19 |

| Portable Brinell standardized block | 200±50HBS | 75 x 75 x 22 | 1 |

| Hammer-hitting type Brinell standardized block | 175-225HBS | 150 x 12 x 12 | 0.17 |

| Micro-Vickers standardized block | 200-300HV0.05 200-300HV0.1 400-500HV0.1 400-500HV0.2 700-800HV0.2 700-800HV0.5 700-800HV1 |

Φ25 x 5 | 0.03 |

| Leeb standardized block | 790±40HLD | Φ90 x 55 | 2.7 |

| Shore standardized block | 95±4HSD 60±4HSD 30±4HSD |

65 x 52 x 15 | 0.39 |