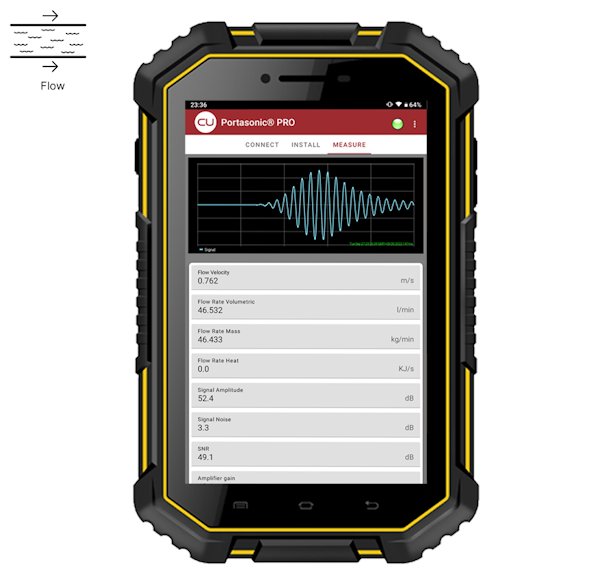

The Portasonic® PRO is a handheld tablet-based ultrasonic clamp-on flow meter with pressure prediction software for calculating internal pipe pressure from measured flow rates.

Coltraco Portasonic PRO

Description

The Portasonic® PRO combines the functionality of the Portasonic 2.FL0 in measuring flow rates non-invasively with the Portasonic CALCULATOR, which is the first instrument capable of determining the internal pressure within pipes, using non-invasive, external flow technology.

Within this integrated device, users can accurately measure the liquid flow rates in their pipes non-invasively using one of the world’s leading non-invasive flow meter technology for a wide variety of maintenance and inspection needs – accurate to 0.5% of the true flow rate. The technology has been independently verified at an ISO 17025 laboratory, capable of meeting accuracies of +/- 0.5% of the true flow rate.

Users are then able to input this measured flow rate and pipe information into the device to calculate internal pipe pressures. The algorithms involved in calculating internal pipe pressures use an empirical equation derived from the laws of fluid dynamics to calculate the liquid pressure to within 5% accuracy. Our knowledge of the properties of 19+ different fluids and 23 different common pipe materials has enabled us to acquire a detailed understanding of the pressure required to drive different fluids at a variety of flow speeds.

Why choose non-invasive ultrasonic transit time technology over inline flow meters?

- Clamp on, portable and non-invasive which allows a single instrument to be used across multiple different pipes / pipe sections

- No installation costs such as drilling into pipes, therefore no downtime to the pipe network is present

- As there is no contact with the fluid being measured, there is no risk of pressure loss throughout your pipe network

- As with above, the fluid cannot damage the flowmeter, which could contribute to a longer lifespan and lower maintenance cost compared to inline flowmeters which are in contact with the fluid and risk being damaged by the pressurised flowing fluid

Why measure internal pipe pressure?

The pressure in a pipe system must be closely monitored to ensure it does not exceed safe tolerances. Critically high pressures can lead to pipe failure, damage to property, and risk to personnel. The durability and safe functioning of pipes, pumps, and related equipment are also affected by pressure. Knowledge of the pressure in a pipe system is therefore important for ensuring that the flow is occurring as expected, in a safe and sustainable manner.

Main Features of the Portasonic® PRO

- Measure flow rates non-invasively and calculate pressure quickly and easily using an intuitive touchscreen tablet

- Save data to records and export via USB or email to ensure traceability

- Filter records by date or by pipe

- Accounts for temperature and material roughness to produce results of the highest possible accuracy

- Determine if your pipe is pressurised to within a safe tolerance

Download Brochure

What's in the box

- Portasonic PRO 7” tablet:Handheld, ruggedised, rechargeable 7-inch touchscreen tablet

- Processing Unit with Pair of DM10 Standard Sensors for pipes DN15 – DN700:Compact, ultrasonic flow measurement sensors combined with processing unit

- Pair of Beaded Chain Clamps (set of 2) :Metallic chain clamps for mounting flow measurement sensors with ease

- Measuring Tape :For measuring the distance between flow measurement sensors during set-up process

- Ultrasonic Couplant:For ensuring good contact between sensors and pipe wall

- USB Type-C to USB Type-A adaptor:To allow direct connection between the flow sensors to table and to allow direct plug-in of a USB stick for exporting data

- USB Type-C Cable:For charging and data transfer

- Power adaptor:For charging the tablet

- USB Stick:To save your data on

- User Manual:Contains further information regarding functionality of the instrument and how-to-use

- Installation Manual :Contains further guidance on how to install the flow measurement sensors on the pipe

- Calibration Certificate:As evidence that the unit has been tested and shown to be working before dispatch

- Robust Carrying Case:For portability and ease of carrying the equipment