R-Evolution is an ultrasonic phased array probe housed in a light-weight glycerine-filled roller, delivering fast immersion quality C-scan inspections in the palm of your hand. Designed to minimise operator fatigue, R-Evolution is small and light making it ideal for use on large areas and particularly overhead inspections.

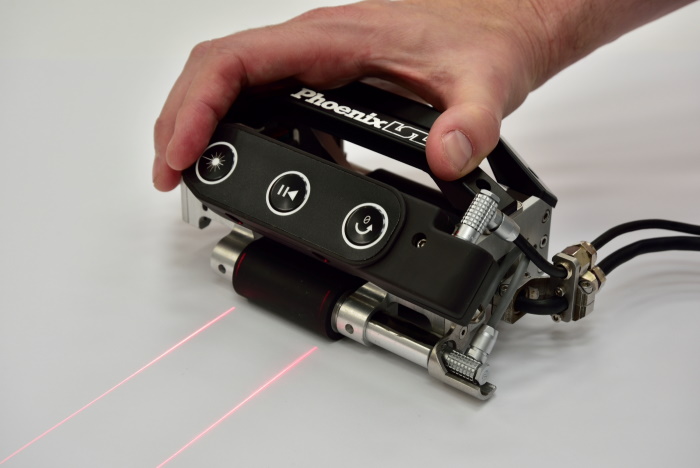

Phoenix R-Evolution Roller Probe

Description

R-Evolution is an ultrasonic phased array probe housed in a light-weight glycerine-filled roller, delivering fast immersion quality C-scan inspections in the palm of your hand. Designed to minimise operator fatigue, R-Evolution is small and light making it ideal for use on large areas and particularly overhead inspections.

Applications

Typical applications for R-Evolution include

- Aerospace – In-service c-scans, Bond Inspection, Delamination or defect detection in composites

- Wind Energy – Blade spar, leading and trailing edge bond inspection

- Pipelines and Vessels – Corrosion mapping, Bond testing on overlapping joints

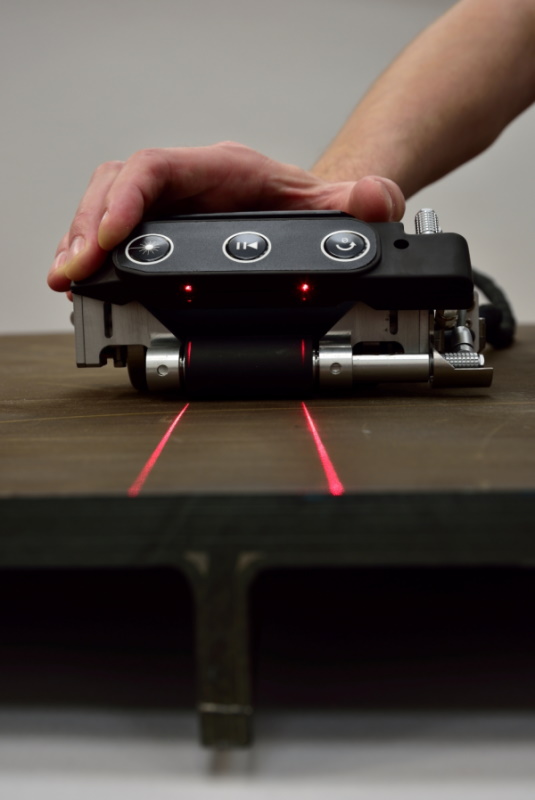

Ergonomic in design, R-Evolution contains an ultrasonic array probe, mounted in a small diameter, glycerine-filled roller. With its durable thin tyre, high frequency probes can be used to give excellent near surface resolution enabling the inspection of thin components.

R-Evolution’s buggy self-normalises on curved surfaces ensuring the array is perpendicular without adjustment. The array angle can additionally be easily fine-tuned externally.

The buggy handle features two line lasers for guidance and buttons that can be configured with appropriate instruments to start, stop or increment scans.

R-Evolution has a single axis encoder for inspecting c-scan strips or can be attached to the Phoenix Tracer for a versatile and portable large area c-scan inspection system

- Fast immersion quality c-scan inspections

- Excellent resolution with high frequencies – up to 10MHz

- Improved near surface resolution enables inspection of thin components

- Ergonomic design to minimise operator fatigue

- Lightweight buggy ideal for overhead inspections and large areas

- Self-normalises on curved components ensuring the array is always perpendicular to the inspection surface

- User-friendly for ease of use in the field

- Accurate scanning with two laser guides to mark the outer extents of the array

- Cost effective solution with interchangeable probes

- Compatible with Tracer for dual-axis, large area inspections Add a Specification Tab