-

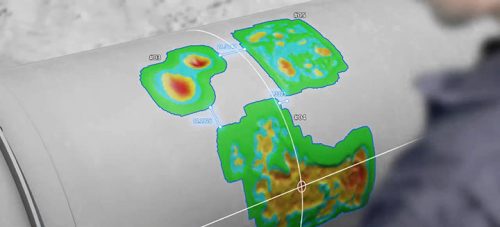

Phased Array Wheel Probe for Corrosion Mapping, Marine Inspection, Aerospace Fuselage Inspection, Aerospace Large Area scanning, and Automotive Testing. As the best alternative to immersion inspection, the WheelProbe 2 offers an impressive 1mm near surface resolution in the latest composite materials using a 5MHz array. Available also with 10MHz, 3.5MHz and 2MHz versions, the WP2 is capable of measuring flaws in other more attenuating materials. Weighing only 1Kg and 45% lighter than the earlier generation, this more versatile model offers distinct advantages for the operator, especially when scanning large areas upside down.

Phased Array Wheel Probe for Corrosion Mapping, Marine Inspection, Aerospace Fuselage Inspection, Aerospace Large Area scanning, and Automotive Testing. As the best alternative to immersion inspection, the WheelProbe 2 offers an impressive 1mm near surface resolution in the latest composite materials using a 5MHz array. Available also with 10MHz, 3.5MHz and 2MHz versions, the WP2 is capable of measuring flaws in other more attenuating materials. Weighing only 1Kg and 45% lighter than the earlier generation, this more versatile model offers distinct advantages for the operator, especially when scanning large areas upside down. -

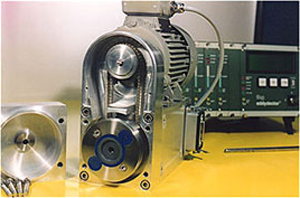

Phased Array transducers with DAAH (Detachable Active Array Head) provides a unique phased array transducer solution by splitting the array from the cable. This concept also yields advantages in cost at purchase but also for maintenance in the long run as a cable is much less expensive to repair then replacing a phased array probe.

Phased Array transducers with DAAH (Detachable Active Array Head) provides a unique phased array transducer solution by splitting the array from the cable. This concept also yields advantages in cost at purchase but also for maintenance in the long run as a cable is much less expensive to repair then replacing a phased array probe. -

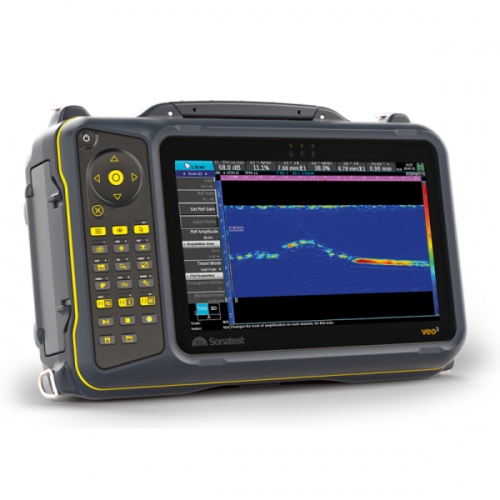

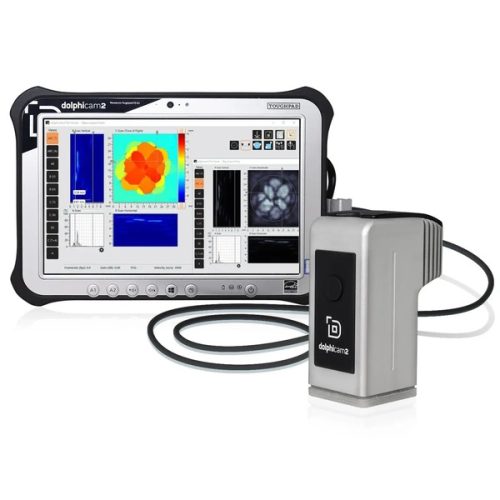

Portasonic 2.FLO portable clamp on flow meter: The Award Winning Portasonic to non-invasively measure the flow of any clean liquid through a wide variety of pipes. Can also be combined with the Portasonic® 2.FLO Calculator to calculate and store internal pressure readings! Non-invasive utrasonic flow technology allows the internal flow of a pipe to be measured without the need to modify or acess the internals of the pipe in any form. Simply place sensors on the outside of the pipe, go through the setup process and instantly measure the speed and volume of liquid flowing through the pipe. This is used throughout proces industry, fire hydrant testing and numerous other testing and maintenance applications.

Portasonic 2.FLO portable clamp on flow meter: The Award Winning Portasonic to non-invasively measure the flow of any clean liquid through a wide variety of pipes. Can also be combined with the Portasonic® 2.FLO Calculator to calculate and store internal pressure readings! Non-invasive utrasonic flow technology allows the internal flow of a pipe to be measured without the need to modify or acess the internals of the pipe in any form. Simply place sensors on the outside of the pipe, go through the setup process and instantly measure the speed and volume of liquid flowing through the pipe. This is used throughout proces industry, fire hydrant testing and numerous other testing and maintenance applications. -

The Portasonic® Calculator is the first instrument capable of determining the internal pressure within pipes, using non-invasive, external flow technology. This calculator is designed to operate alongside our Portasonic 2.FLO® Ultrasonic Flow Meter. The Portasonic is one of the world’s leading non-invasive flow meters and is an essential tool for a wide variety of maintenance and inspection needs.

The Portasonic® Calculator is the first instrument capable of determining the internal pressure within pipes, using non-invasive, external flow technology. This calculator is designed to operate alongside our Portasonic 2.FLO® Ultrasonic Flow Meter. The Portasonic is one of the world’s leading non-invasive flow meters and is an essential tool for a wide variety of maintenance and inspection needs.